Automatic cleaning system

Excellent and consistent cleaning results

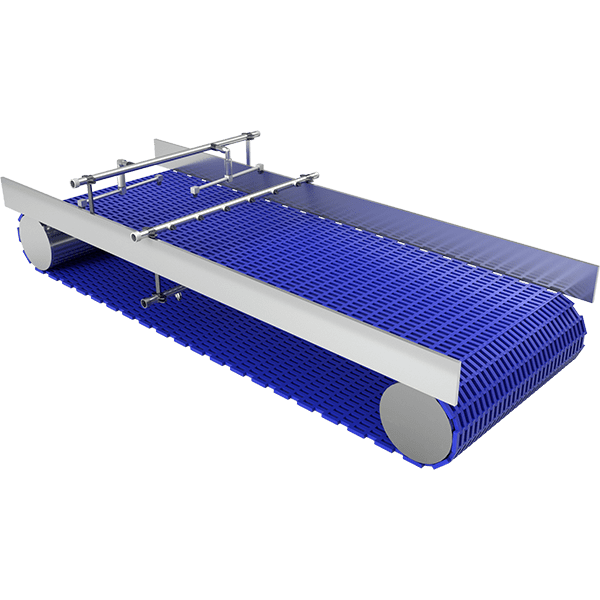

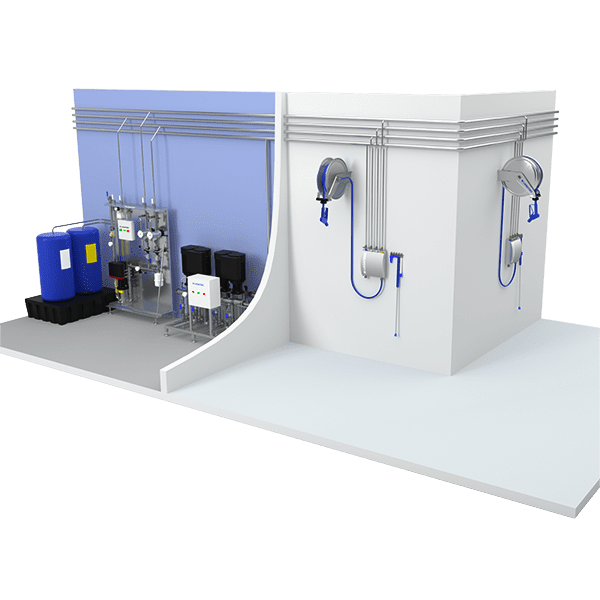

The automatic Cleaning System, ACS II, consists of a controller unit and valve units for water, chemical, and disinfectant solutions. The system is designed to clean all conveyor belts, elevator belts, etc, automatically.

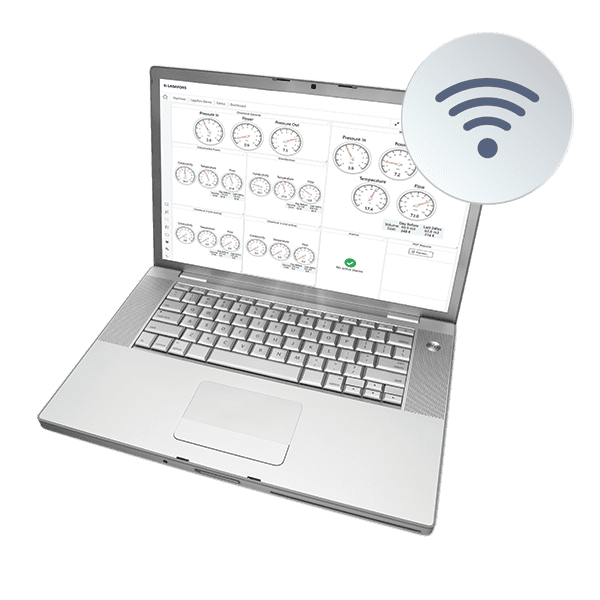

The design is based on Lagafors’s well-known VMS II satellite station series, and from a hygienic point of view, the unit has been adapted to the food processing industry. The ACS II system is ready to be connected to any pressurized water unit and the VCC II dosing central for chemical and disinfectant solutions. The unit is user-friendly, as well as easy to use and maintain. The system gives the customer consistent cleaning results, which means better hygiene, time-savings, and reduced water, chemical, and disinfectant consumption.

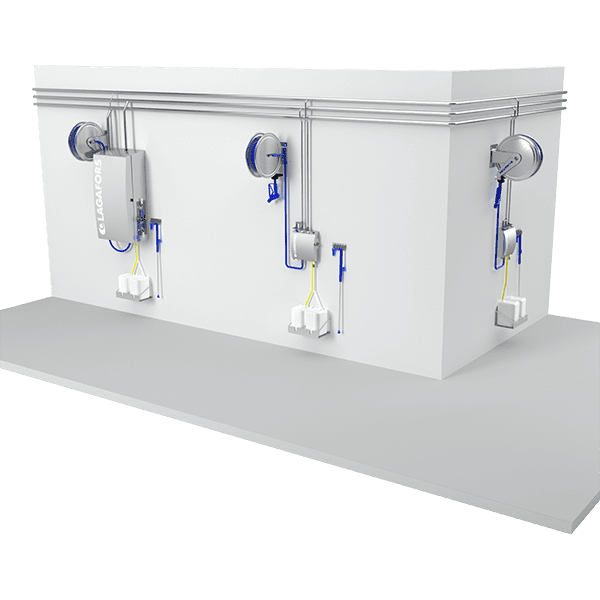

The ACS II unit is comprised of the following:

- Stainless steel controller cabinet with Siemens PLC and touch display. As well as AS-i bus communication.

- Stainless steel valve cabinet with pneumatically controlled valves to regulate the water flow.

- Stainless steel valve cabinet (Combi) with pneumatically controlled valves to regulate water, chemical, and disinfectant solutions.